1. They are made from natural raw materials that are widely available and sourced locally, providing employment, particularly in rural areas where job prospects can be limited

Clay bricks and blocks and clay roof tiles are natural products, because they are basically made of earth, water and fire.

Clay is the main ingredient of ceramic products and from a geological point of view is basically inexhaustible (and in some cases renewable, i.e. continuous sedimentary deposition).

Clay brick and tile manufacturing plants are frequently situated alongside clay deposits thereby minimizing the impacts of transporting raw materials to the factory.

The location of brickworks, tile works and their quarries in rural and semi-rural areas has enabled the industry to provide long-term, stable employment to small neighbourhoods and communities. An established relationship between manufacturer and community covering all aspects of extraction and restoration provides advantages for both sides. Such good practices cover site appearance, prevention of pollution, reduction of ecological impact, restoration and aftercare. Additionally the industry has gone to great lengths to improve its presence in these communities and to support local traditions and initiatives. For example, storage areas are surfaced in tarmac and regularly cleaned in a bid to reduce airborne dust, while fast growing hedges are often planted to reduce visual impact.

Heaps of clay raw material (Uwe Strasser for Wienerberger AG)

2. Extraction is responsible: exhausted clay pits are transformed into nature reserves, amenity lakes, agricultural areas or waste repositories

The extraction of clay for construction products is a small percentage of the total mineral extraction. If deposits lie deep, land usages rates are modest, whilst in delta areas extraction is managed with minimal disruption.

Although the extraction of clays and sands has an environmental impact, restored land over exhausted clay pits also has potential benefits, such as the creation of nature reserves, amenity lakes, agricultural or forestry areas and in some cases the formation of repositories for various forms of waste.

Moreover, clay pits very often represent an opportunity for biodiversity, creating or restoring natural habitats, where animals and plants take shelter. This sometimes leads to the discovery and preservation of archaeological and paleontological remains.

The local extraction of clay in Europe guarantees highly regulated labour conditions. One of the main areas covered by EU labour law is working conditions ensuring high levels of employment and social protection throughout the EU. Building materials imported from outside the European Union may not be so responsibily sourced, because they are not required to comply with the EU labour law.

Clay extraction in the Netherlands (from K3 Delta for KNB)

3. The production process is resource and energy efficient

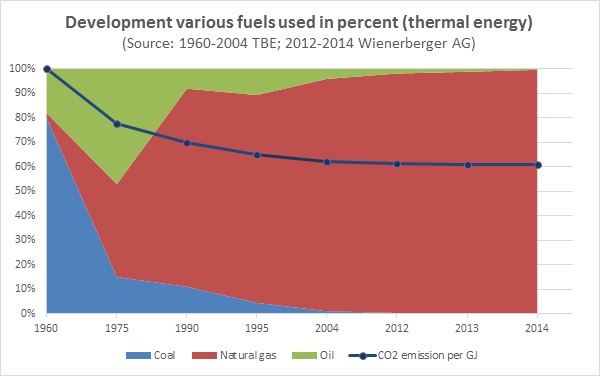

The energy consumed during the manufacture of clay products is primarily that used in forming, drying and firing. Since energy costs are an important part of total production costs (up to 30%), the clay industry has always closely monitored its energy usage. Ecology and economy are often linked and the European brick and tile industry has not waited for statutory regulation before investing in better energy efficiency. Firing is responsible for the exceptionally long life of our products.

Throughout the industry, the widespread change to gaseous fuels and improvements in drying, kiln technology and control have resulted in a progressive reduction in energy use and a marked reduction in emissions. In recent years, there is an increasing number of brick makers that use biofuel.

The primary process improvements are:

improved design of dryers and kilns

computer control of drying and firing regimes

Heat recovery systems from kilns (mainly hot air from cooling zones of kilns ducted to dryers)

product modifications or innovations

The implementation of renewable energy is in constant progress:

production or use of green electricity

gas produced from landfill can be used in nearby clay brick and roof tile production plants or elsewhere, thereby reducing the reliance on non-renewable energy sources.

Renewable resources are also present in many ceramic production processes where biogenic additives, such as sawdust can be added to the raw clay. The utilisation of such renewable additives reduces product weights and increases their insulating performance.

Whilst the production process of clay construction products has made tremendous improvements in energy efficiency, low rates of water consumption and water wastage are also fundamental characteristics of clay product manufacture. Similarly is the case with regard to waste. There is no waste in the production process because it is possible to reuse/recycle clay at any stage.

Clay preparation at production plant Hennersdorf, Austria (Uwe Strasser for Wienerberger AG)

4. They provide a comfortable and healthy environment in buildings

Brick-built buildings offer high levels of comfort. Some aspects are difficult to quantify, whilst others can be clearly measured or tested.

These include:

acoustic performance / sound insulation,

thermal comfort (surface temperature of walls, difference between surface and room temperature, air movements in the room),

ability of the wall to absorb moisture and return it to the indoor air,

thermal mass / heat storage, cool in summer, warm in winter

no toxic emissions emanating from the building fabric into the internal environment,

high levels of safety in case of fire, flood and burglary,

high levels of flexibility inherent in the building’s design.

The indoor climate can have a significant effect on an occupant’s sense of well-being and clay perform very well in this respect. The high thermal mass of clay building materials means that they are ideal for use in solid, cavity and externally insulated walls, reducing fluctuations in temperature by absorbing thermal energy when the surroundings are higher in temperature than the mass, and giving thermal energy back when the surroundings are cooler. In other words, the clay wall, floors and roofs will reduce the rate at which the building will heat up when exposed to sunlight and will slow down the rate at which the building will cool at night. The porosity of clay bricks allows them to absorb moisture from the air when the relative humidity is high and to return this moisture when the indoor air becomes drier. Special attention must be given to thermal (cold) bridges such as may occur at corners and window frames, where surface temperatures are significantly lower. The clay brick industry can provide design solutions to minimize the effect of these details.Several studies show that clay construction products do not emit any harmful substances, such as volatile organic compounds, into indoor air. Clay bricks and blocks can therefore be seen as the perfect material to provide a healthy indoor air quality.

Clay roof tiles contribute to:

hydrothermal comfort by protecting the building from solar overheating, rain and snow;

an excellent acoustic insulation thanks to its combination of sound-absorbing materials. A pitched roof allows the owners to sleep soundly even during heavy rainfall.

Brick walls provide relief from noise due to their capacity to reliably absorb low frequency sounds thus helping to cut out external traffic noise, bass music coming from other buildings and dampening any sound coming from inside a building such as loud TV programmes. This natural sound protection system means that the inside of a well-designed brick building remains pleasantly quiet when it is noisy outside and vice versa.

Belgian brick school (Belgian Brick Federation)

5. They offer infinite creative solution to designers

Due to the versatility of clay building products, they can be easily adapted to new requirements, techniques and methods of construction. The development and continuous improvement of clay bricks and blocks, roof tiles and pavers, their technical performance and the constant introduction of new designs, shapes and colours make them perfectly suitable to innovative and future-oriented buildings.

Buildings made with clay products are flexible. Changes are possible both during the construction process and throughout the building’s life. This makes clay buildings open towards changing needs and usages.

Modern Belgian brick house ((Belgian Brick Federation)

6. They contribute to a properly insulated building envelope

A properly insulated building envelope not only increases comfort but also significantly reduces heating and cooling costs incurred over the lifespan of a building. From both financial as well as environmental perspectives, a properly insulated building envelope is key.

Clay brick cavity walls and monolithic clay block walls with additional insulation can in principle reach any required U-value by varying the insulation thickness. In many countries the trend is toward low energy houses (heating energy requirement approx. 40-60 kWh/m²a) or even passive houses (heating energy requirement < 15kWh/m²a). While classical external insulation (ETICS – External Thermal Insulation Composite Systems) has only a limited lifespan and needs maintenance and/or replacement after some years depending on various circumstances, the renewal of the insulation becomes unnecessary for cavity walls and for innovative bricks with integrated insulation. They offer a well-insulated wall for a lifetime.

As well as insulation, thermal mass makes a significant contribution to the thermal performance of a building. When considering the internal environment of a building, it is important – especially in summer – to have sufficient thermal mass to store the solar energy absorbed by the construction (see also Living comfort and Internal environment). Thermal mass also has a direct effect on the energy required for cooling. Clay brick walls can store solar and internal heat gains and radiate the energy out when it is needed. Moreover, the use of clay bricks associated with clay lining bricks for the edge of floor slabs is an easy and cheap solution to treat thermal bridges.

Thermal insulated clay block (Uwe Strasser for Wienerberger AG)

7. Clay-based buildings are robust and resistant to fire and floods

Clay products are non-combustible; clay brick and block walls provide excellent fire resistance and do not emit any hazardous substances or gases. Furthermore, they do not normally suffer structural damage during a fire and can therefore continue their loadbearing function after the building has been refurbished. Clay brick walls can also withstand saturation from flood water and burst pipes without being adversely affected structurally. Brick houses provide stability in the face of numerous natural hazards, namely storms, avalanches and earthquakes,. Well designed and executed houses built with new clay masonry products can withstand such extraordinary impacts and provide high levels of security from intruders. Clay roofing tiles are inert materials. Therefore, they are non-flammable and there is no emission of toxic gases in case of fire. Rainwater runoff can be collected and stored for use.

Construction of robust walls (Filip Dujardin for Belgian Brick Federation)

8. They have a lifecycle of over a century and require little or no maintenance

Brick buildings can last almost forever, because bricks are highly durable. Maintenance costs for clay brick wall constructions are generally very low because they require little attention over their very long lifespan. In the case of rendered walls, the only regular maintenance is painting, which may be necessary after 30 years, depending on the location of the building. After 50 to 60 years, the wall has to be re-rendered completely. Clay brick cavity walls normally require no maintenance or repair over their very long lifespan and are highly durable and resistant to environmental pollution. Even when monolithic clay block walls are used with additional external insulation, they will require no maintenance or repair. The only costs incurred will be the renewal at specific intervals of the external insulation. This normally has a shorter lifespan than the clay brick wall and has to be renewed at specific intervals, depending on the location of the building and the type of insulation used. The replacement of insulation is unnecessary if the insulation is integrated into the clay block. Regular maintenance of roof tiles is easy and can be scheduled to consist of visual inspections and removal of leaves, debris, mosses and lichens that may restrict the flow of water off the roof slope. Any broken tiles can easily be replaced and the function of ventilation components checked and cleared if necessary to ensure adequate air flow into the roof void.

Traditional building in Italy (ANDIL)

9. Clay-based buildings preserve local architectural heritage across Europe

Bricks and tiles have shaped the built environment for centuries. Generations of European architects, builders, bricklayers and tilers have used them to build villages, towns and cities. Local traditions of roof tiles and bricks not only reflect the vernacular but also climate and environment in their particular patterns all across Europe. Such widespread use is not accidental; Europeans have been aware of the technical and aesthetic qualities of clay building products for centuries. The versatility of clay building products has allowed their adaptation to new techniques and methods of construction, whilst the constant introduction of new colours and sizes and the improvement of technical performance has challenged designers. As the European building styles are constantly evolving, so clay building products are being continuously developed. Innovation allows them to meet the requirements of the 21st century whilst preserving our built heritage.

Italian architectural heritage (ANDIL)

10. Clay based buildings maintain high economic value over time and can be passed down to the next generations

Buildings built from clay materials not only have a high monetary value but their longevity means they are passed on through the generations. Clay roof tiles and bricks have a life span in excess of 100 years. As well as their technical qualities, it is also their aesthetical appearance which reflects the cultural heritage. Brick buildings are extremely flexible, making them ideal for extension and adaption for the next generation. Recent research has highlighted the enduring qualities of brick buildings. A Dutch study by H. Van Nunen showed that the average lifetime of a brick house in the Netherlands is 120 years.

Manual production of accessory roof tiles (Uwe Strasser for Wienerberger AG)

11. Our contribution to circular economy

Despite the potential long life of clay brick buildings (well in excess of a 100 years), they are sometimes demolished well before the end of their technical life. When a building is demolished, the clay bricks and roof tiles can continue their useful life by being reused in a new building.

Possible uses for clay recycling materials are:

Reuse as bricks and tiles

Depending on the raw material and mix, scraps from the production process are commonly reused internally for the production of new bricks.

Clay bricks and roof tiles have traditionally been much sought-after materials after demolition for use innew and renovated buildings. In many countries, , the re-use of bricks and roof tiles has increased in recent years as builders and designers strive to create modern buildings with traditional appearance.

Filling and stabilizing material for infrastructure works

For many years, masonry waste and scrap bricks have been used to fill and stabilise minor roads, especially in wet areas such as woods and fields. The practice is common in countries that lack adequate stone supplies, such as Denmark. The material is generally used uncrushed.

Crushed clay bricks, roof tiles and other masonry can be used on larger road building projects, especially as unbound base material. Although crushed masonry can be used for lightly trafficked roads, it is not suited for heavy vehicles due to the risk of deformation. Waste clay material replaces natural materials, such as sand and gravel, which are normally used in large amounts for this purpose. In some cases, crushed masonry can form part of a mix that may also contain concrete and natural aggregate.

Aggregates for in-situ and precast concrete and mortars

Crushed clay bricks and other masonry can also be used to level and fill pipe trenches. The crushed material will replace natural materials such as sand and will therefore cause fewer disturbances to the landscape. Crushed masonry used for this purpose must be free of any contaminants that could leach and cause ground water pollution.

Aggregates for calcium silicate masonry units

Crushed clay bricks, tiles and other masonry can also be used as aggregate in calcium silicate masonry units. The crushed material replaces other raw materials such as sand reducing the need to extract virgin material from the land.

Tennis sand

Sand for surfacing tennis courts is produced by crushing red bricks and roof tiles. Different bricks will give different qualities and colours of tennis sand. Clinker quality will have numerous benefits:

Better water drainage

Unique colour

Greater density (less wind scatter)

No moss problems

Plant substrates

Crushed bricks and tiles can also be used to form substrates for growing plants. The material may be mixed with other substances used in plant production, e.g. composted organic materials. This material is especially suited for green roofs. Flat roofs are covered with a dense polymer membrane and overlaid with 10-30 cm of the crushed brick and tile material.

Bricks can be reused in many ways (Uwe Strasser for Wienerberger AG)

Another possibility for crushed bricks and masonry is as fill material around tree roots where traffic would otherwise compact the soil and hinder its ability to absorb air and water. The use of recycled ceramic waste material will save on virgin raw materials, but it must be free from any contaminants that could leach and adversely affect the plants and the surrounding area.

Bricks can be reused in many ways (Uwe Strasser for Wienerberger AG)

12. Providing solutions for sustainable buildings

EPDs are the data basis for sustainability assessment of buildings, which should always take into account the three pillars of sustainability (environment, economic and social). EPDs are generated for single products or product groups (e.g. clay blocks). Standards have been developed by CEN TC350 and implemented by the national program operators. Even if EPDs remain a voluntary tool, the use of EPDs is becoming increasingly important in Europe as some Nations require registration of the environmental performance when environmental claims are linked to building products. EPD’s are also used as the basis for green public procurement and specifically for the assessment of the environmental performance of buildings. The efficient production process and very long service life of ceramic building products result in favourable environmental profiles.

EPDs of clay construction products can be found on various national EPDs programme operators. Below is a list of such national EPD operators: